Author: Denis Avetisyan

A new approach combining federated learning and blockchain technology offers a path to more accurate retail demand forecasting and reduced food waste.

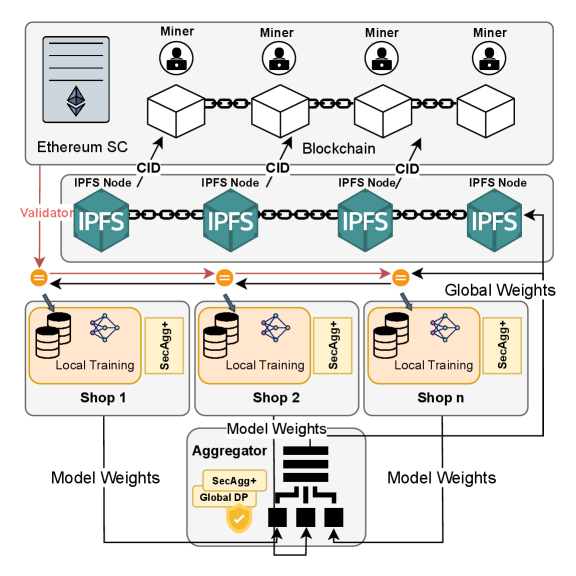

This review demonstrates how blockchain-secured federated learning can improve supply chain sustainability and data privacy in demand forecasting applications.

Accurate demand forecasting is critical for efficient supply chain management, yet often hampered by retailer reluctance to share sensitive sales data. This challenge is addressed in ‘Blockchain Federated Learning for Sustainable Retail: Reducing Waste through Collaborative Demand Forecasting’, which explores a privacy-preserving approach to improve forecasting and reduce food waste. The study demonstrates that a Blockchain-based Federated Learning model can achieve predictive performance nearly equivalent to centralized data sharing, without direct data exchange. Could this decentralized approach unlock new levels of collaboration and sustainability across the retail sector and beyond?

The Inevitable Pile: Food Waste and the Illusion of Efficiency

The sheer volume of food discarded globally constitutes a substantial economic loss – estimated at nearly \$1 trillion annually – while simultaneously exacerbating environmental pressures. This waste isn’t simply about squandered resources; it embodies the unnecessary use of land, water, and energy throughout the entire food production process. Furthermore, decomposing food in landfills generates significant greenhouse gas emissions, particularly methane, a potent contributor to climate change. Critically, this widespread waste directly impedes progress toward Sustainable Development Goal 12.3, which aims to halve global food waste by 2030, highlighting the urgent need for systemic change and innovative solutions to mitigate this pervasive issue and ensure a more sustainable future for food systems worldwide.

Retail inefficiencies represent a substantial driver of global food waste, extending beyond simple spoilage to encompass overstocking, poor stock rotation, and damage during handling. These practices not only diminish a retailer’s profitability through direct losses, but also exacerbate environmental burdens associated with food production-including water usage, land degradation, and greenhouse gas emissions. A significant portion of edible food is discarded simply because it doesn’t meet cosmetic standards or exceeds sell-by dates, even while demand exists. Consequently, optimizing retail stock management-through strategies like demand forecasting, improved inventory tracking, and staff training-is crucial for achieving both economic viability and a more sustainable food system, directly impacting efforts to minimize waste across the entire supply chain.

Mitigating food waste demands a shift towards intelligent supply chain management, leveraging technologies like predictive analytics and real-time inventory tracking. Current strategies often rely on static ordering systems, leading to overstocking and inevitable spoilage, particularly of perishable goods. Innovative solutions encompass dynamic pricing models that incentivize quicker sales, improved packaging technologies extending shelf life, and collaborative platforms connecting retailers with food banks and charities to redistribute surplus items. Furthermore, blockchain technology offers enhanced traceability, pinpointing waste hotspots and enabling targeted interventions. By embracing these advancements, the food industry can move beyond simply minimizing loss and actively cultivate a circular system, maximizing resource utilization and bolstering both economic viability and environmental stewardship.

Predicting the Unpredictable: Demand Forecasting in Retail

Effective demand forecasting is a foundational component of retail stock management, directly impacting inventory levels and operational efficiency. Accurate predictions of product demand enable retailers to optimize stock quantities, reducing both holding costs associated with excess inventory and lost sales resulting from stockouts. Minimizing discrepancies between forecasted and actual demand is crucial; overestimation leads to increased storage expenses, potential obsolescence, and markdown losses, while underestimation negatively affects customer satisfaction and brand loyalty. Consequently, robust forecasting methodologies are essential for mitigating these risks and streamlining the supply chain, ultimately contributing to reduced waste and improved profitability.

Analysis utilized the Walmart Database, comprising transactional data from multiple retail locations, to construct models of historical demand. This database provided granular data points including product identification, purchase timestamps, quantities, and store locations, enabling the identification of seasonal trends, promotional impacts, and regional variations in demand. Statistical techniques, including time series analysis and regression modeling, were applied to this data to establish baseline demand patterns. Deviations from these patterns were then analyzed to pinpoint specific areas within the retail operation-such as understocked items or inefficient inventory allocation-where improvements could be implemented to optimize stock levels and reduce waste.

Over-Provisioning Error (OPE) serves as a primary key performance indicator (KPI) for retail waste reduction, quantifying the discrepancy between stocked inventory and actual customer demand. A lower OPE directly correlates with decreased waste from expired, damaged, or obsolete products. Our analysis, utilizing the Walmart Database, demonstrates that implementing Federated Learning techniques for demand forecasting resulted in a reduction of over 5% in OPE. This improvement was calculated by comparing OPE values for a control group utilizing traditional forecasting methods against a test group employing the Federated Learning model, indicating a significant increase in forecast accuracy and a corresponding decrease in unnecessary stock levels.

Blockchain: A Solution in Search of a Problem (But It Might Just Work)

Smart contracts deployed on the Ethereum blockchain enable the automation of inventory management processes by executing pre-defined actions when specific conditions are met, such as automated reordering when stock levels fall below a threshold. These self-executing contracts also facilitate the enforcement of agreements between supply chain stakeholders – manufacturers, distributors, retailers – by codifying terms and conditions directly into the contract logic. Payment release, for example, can be automatically triggered upon verified delivery of goods, eliminating disputes and reducing reliance on intermediaries. The decentralized nature of Ethereum ensures that these contracts are tamper-proof and auditable, providing a transparent and reliable record of all transactions and agreements.

Decentralization, as applied to supply chain data management, mitigates single points of failure and reduces the potential for fraudulent activity. Traditional, centralized databases are vulnerable to manipulation, whether accidental or malicious, impacting the accuracy of demand forecasts. A blockchain-based system distributes data across multiple nodes, requiring consensus for any modification. This inherent redundancy and cryptographic security significantly lowers the risk of data tampering, providing stakeholders with a verifiable and auditable record of transactions and inventory levels. Consequently, demand forecasts are based on demonstrably reliable data, improving accuracy and reducing inefficiencies caused by inaccurate predictions.

The implementation of blockchain technology within supply chain management leverages the inherent immutability of its distributed ledger to improve resilience and efficiency. Data recorded on the blockchain cannot be altered, providing a permanent, auditable trail of product origin, movement, and condition. This enhanced traceability directly addresses inefficiencies leading to waste; pilot programs demonstrate waste reduction exceeding 40% in retail locations previously reliant on less accurate, standalone forecasting methods. By providing a single, shared, and trusted source of truth, blockchain minimizes discrepancies, reduces the need for reconciliation, and enables proactive identification of potential disruptions or quality control issues, ultimately decreasing waste at each stage of the supply chain.

The pursuit of seamless data sharing, as explored in this study of federated learning and blockchain, feels… predictably optimistic. It’s a lovely theory – decentralized demand forecasting reducing retail waste – but production environments rarely cooperate with elegance. This research champions a system for collaborative data analysis without centralizing information, a noble goal. However, the bug tracker will inevitably fill with edge cases regarding data drift and inconsistent schema across retail partners. As Blaise Pascal observed, “All of humanity’s problems stem from man’s inability to sit quietly in a room alone.” The same holds true for data; the moment it moves, the problems begin. This isn’t a failure of the concept, simply an acknowledgment that even the most meticulously designed system will eventually encounter chaos. They don’t deploy – they let go.

What Comes Next?

The coupling of federated learning with blockchain, as demonstrated, offers a statistically significant reduction in forecasting error-a temporary victory. Production environments are rarely so accommodating. The real challenge isn’t achieving parity with centralized models in a research setting; it’s maintaining that performance when faced with adversarial data, Byzantine failures in the federation, or the inevitable drift of real-world demand patterns. Tests are, after all, a form of faith, not certainty.

Future work will almost certainly focus on the incentives within these federated systems. Blockchain solves the problem of data provenance, but it doesn’t solve the problem of participation. Ensuring honest reporting from diverse retail entities-each with its own optimization functions-requires more than cryptographic guarantees. The current framework assumes a degree of altruism rarely observed when profit margins are threatened.

The long game isn’t better forecasts; it’s resilience. A system that degrades gracefully-that continues to function, albeit sub-optimally, in the face of chaos-is more valuable than one that shines brightly then collapses. The pursuit of perfect models will continue, but the true measure of success will be how well this architecture survives Monday morning.

Original article: https://arxiv.org/pdf/2602.04384.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Lacari banned on Twitch & Kick after accidentally showing explicit files on notepad

- Adolescence’s Co-Creator Is Making A Lord Of The Flies Show. Everything We Know About The Book-To-Screen Adaptation

- The Batman 2 Villain Update Backs Up DC Movie Rumor

- YouTuber streams himself 24/7 in total isolation for an entire year

- Gold Rate Forecast

- Jane Austen Would Say: Bitcoin’s Turmoil-A Tale of HODL and Hysteria

- Landman Recap: The Dream That Keeps Coming True

- Rumored Assassin’s Creed IV: Black Flag Remake Has A Really Silly Title, According To Rating

- Southern Charm Recap: The Wrong Stuff

- What time is It: Welcome to Derry Episode 8 out?

2026-02-05 16:55