Author: Denis Avetisyan

A new integrated digital twin environment is poised to accelerate innovation in nuclear plant technology and bolster operational safety through advanced robotics, AI, and cybersecurity.

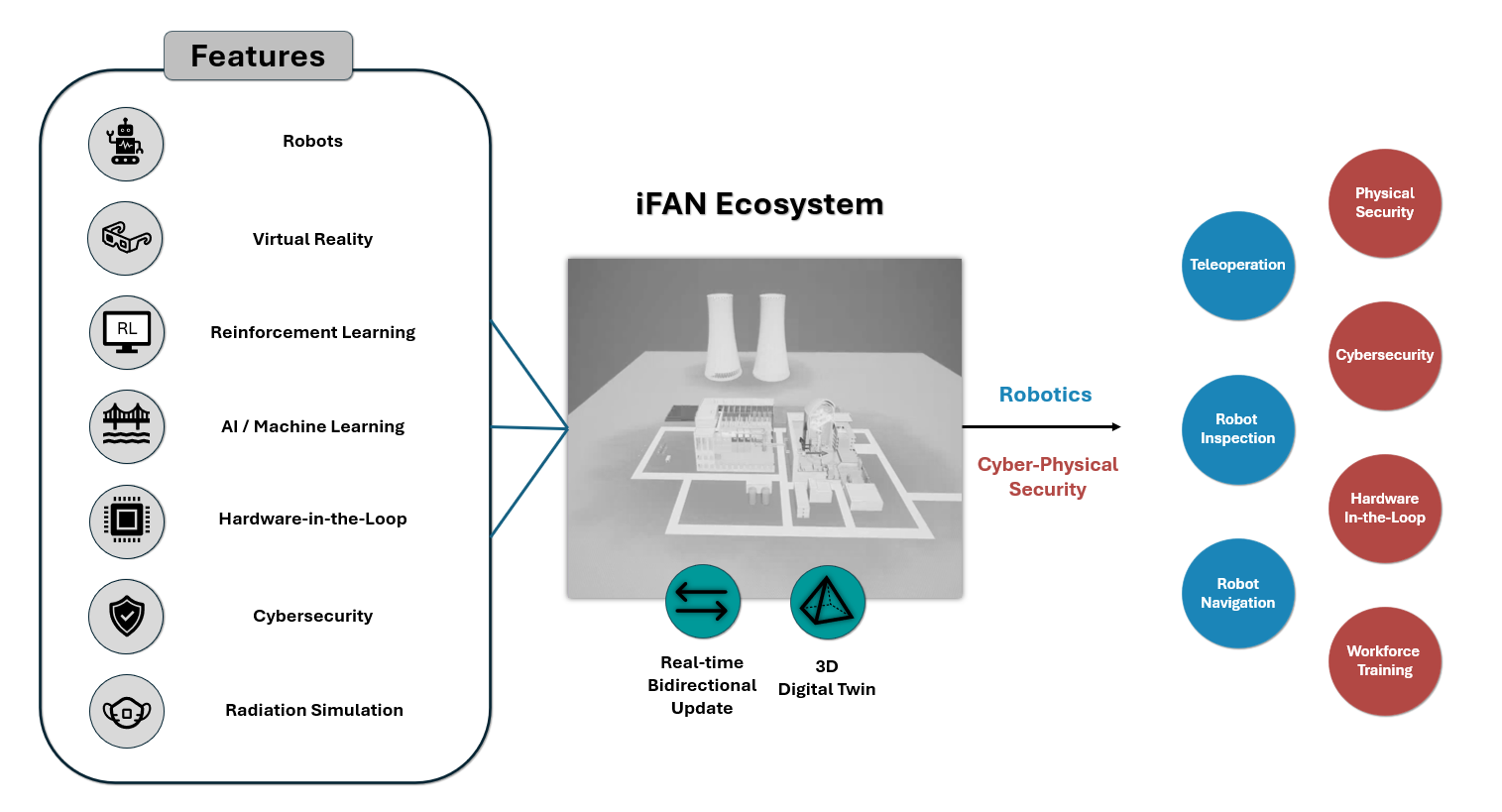

The iFAN ecosystem provides a unified platform for high-fidelity simulation, hardware-in-the-loop testing, and the development of intelligent systems for nuclear power plants.

Despite increasing digitalization and the development of advanced reactor technologies, validating and deploying artificial intelligence, robotics, and enhanced cybersecurity measures within nuclear facilities remains challenging due to a lack of dedicated testing environments. This paper introduces the ‘iFAN Ecosystem: A Unified AI, Digital Twin, Cyber-Physical Security, and Robotics Environment for Advanced Nuclear Simulation and Operations’, a comprehensive digital twin framework designed to address this gap by providing a high-fidelity, real-time virtual testbed. Integrating virtual reality, reinforcement learning, and physics-based simulations, iFAN enables pre-deployment verification of autonomous systems and cyber-physical security protocols. Will this unified environment accelerate the development and secure implementation of next-generation nuclear technologies?

The Inherent Complexity of Nuclear Systems

Nuclear power plants represent a pinnacle of engineered complexity, demanding unwavering attention to both operational stability and potential failure points. These facilities aren’t simply collections of components; they are intricately interwoven systems where the performance of one element directly influences countless others. Maintaining safety and efficiency, therefore, requires constant, comprehensive monitoring – far beyond simple checks – and a proactive maintenance strategy predicated on anticipating potential issues before they escalate. This isn’t merely preventative care; it’s a continuous process of data analysis, predictive modeling, and meticulous inspection, all geared towards ensuring the reliable and secure generation of power from a fundamentally powerful, yet potentially hazardous, energy source. The sheer number of interacting systems – from reactor core components to cooling loops, control mechanisms, and safety redundancies – necessitates a holistic approach to plant management, where even seemingly minor deviations can signal larger, more critical problems.

Historically, ensuring the competence of nuclear plant personnel and validating system performance relied heavily on physical mock-ups and narrowly focused simulations. These approaches, while valuable, present significant drawbacks; constructing and maintaining realistic physical replicas is extraordinarily expensive and logistically challenging, limiting the scope of training and testing. Limited simulations, constrained by computational power and modeling fidelity, often fail to capture the intricate interplay of variables present during abnormal or emergency events. Consequently, operators and engineers may not be fully prepared for unforeseen circumstances, and potential vulnerabilities within plant systems can remain undetected. This creates a critical gap between training preparedness and the demands of real-world operations, necessitating innovative solutions to enhance realism, scalability, and cost-effectiveness in nuclear energy education and safety assessments.

The continued advancement of nuclear energy hinges on the development of significantly improved testing and training platforms. Current methodologies struggle to adequately prepare personnel for the spectrum of potential operational challenges, from routine maintenance to unforeseen emergencies. A robust environment transcends simple simulations; it demands a scalable system capable of realistically replicating plant behavior under diverse conditions, incorporating high-fidelity models of complex interactions. This necessitates investment in technologies like virtual and augmented reality, coupled with advanced data analytics, to provide immersive and adaptive training scenarios. Such a system not only enhances operator proficiency and decision-making but also facilitates the validation of new technologies and procedures, ultimately bolstering plant safety, efficiency, and the long-term viability of nuclear power as a critical energy source.

A Complete Virtual Replica: The Digital Twin Ecosystem

The Digital Twin Ecosystem provides a complete virtual representation of a nuclear facility, allowing for extensive testing, operator training, and performance optimization without incurring the hazards or expenses associated with physical experimentation or plant downtime. This virtual replica mirrors the facility’s components, systems, and processes, enabling simulations of both routine operations and abnormal events. Consequently, modifications to procedures or equipment can be evaluated in a safe, controlled environment, and personnel can practice responses to various scenarios without impacting actual plant operations. The resultant data provides insights for predictive maintenance, improved efficiency, and enhanced safety margins, all achieved through a cost-effective and risk-mitigated approach.

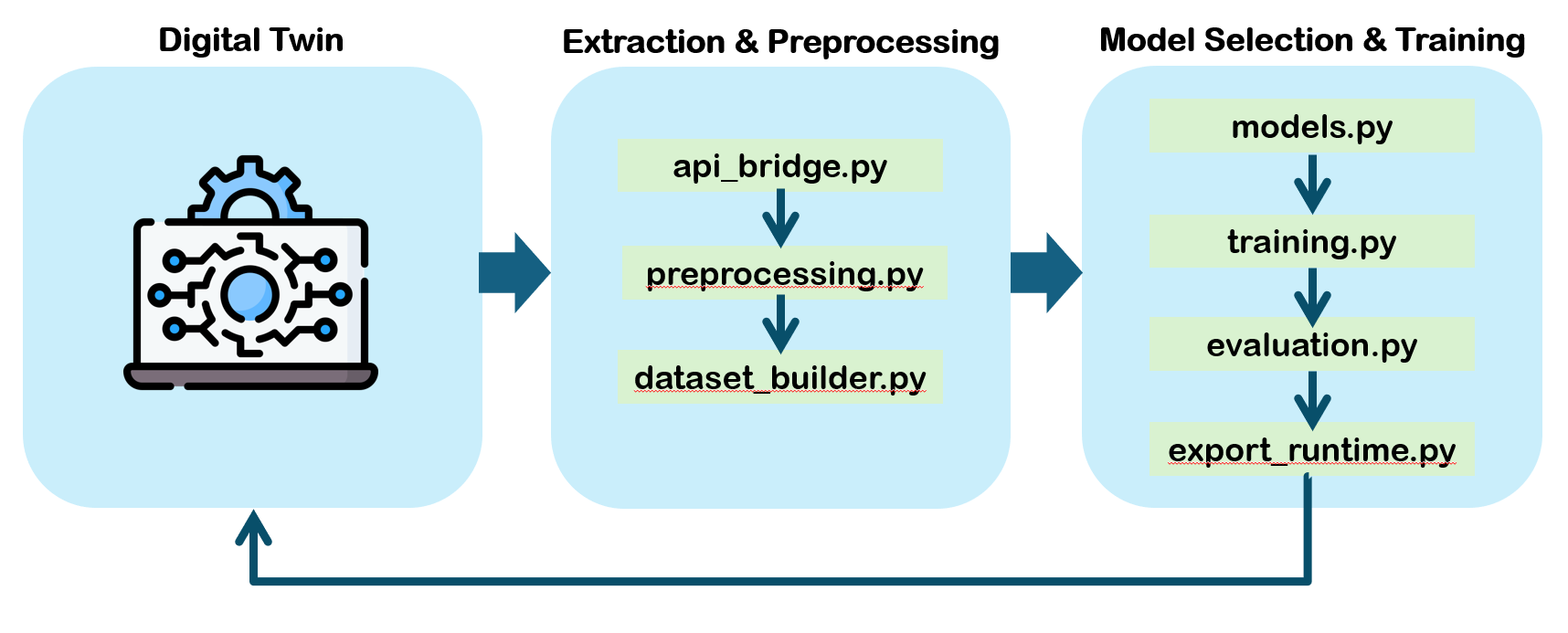

The Digital Twin ecosystem’s accuracy relies on the convergence of several technologies. High-fidelity 3D modeling provides the geometric and spatial representation of the nuclear facility, while a network of sensors continuously collects real-time data on plant parameters – including temperature, pressure, vibration, and radiation levels. This data is then fed into AI and Machine Learning algorithms that process the information, identify patterns, and create a dynamic, predictive model of plant behavior. The integration of these technologies enables the Digital Twin to mirror the physical plant’s current state and forecast future performance with increasing precision, facilitating proactive decision-making and optimized operations.

Utilizing the digital twin environment, nuclear facility operators gain the ability to perform predictive maintenance by analyzing real-time sensor data and simulating potential failure scenarios. This allows for the proactive identification of anomalies and degradation before they escalate into critical issues, reducing downtime and maintenance costs. Performance optimization is achieved through virtual testing of operational adjustments, enabling operators to refine procedures and maximize efficiency without disrupting live plant operations. Enhanced safety protocols are implemented by simulating emergency situations and training personnel in a risk-free environment, improving response times and mitigating potential consequences of real-world events. Data-driven insights from the digital twin support informed decision-making across all operational phases, contributing to a more reliable and secure facility.

Establishing Fidelity: Hardware-in-the-Loop Validation

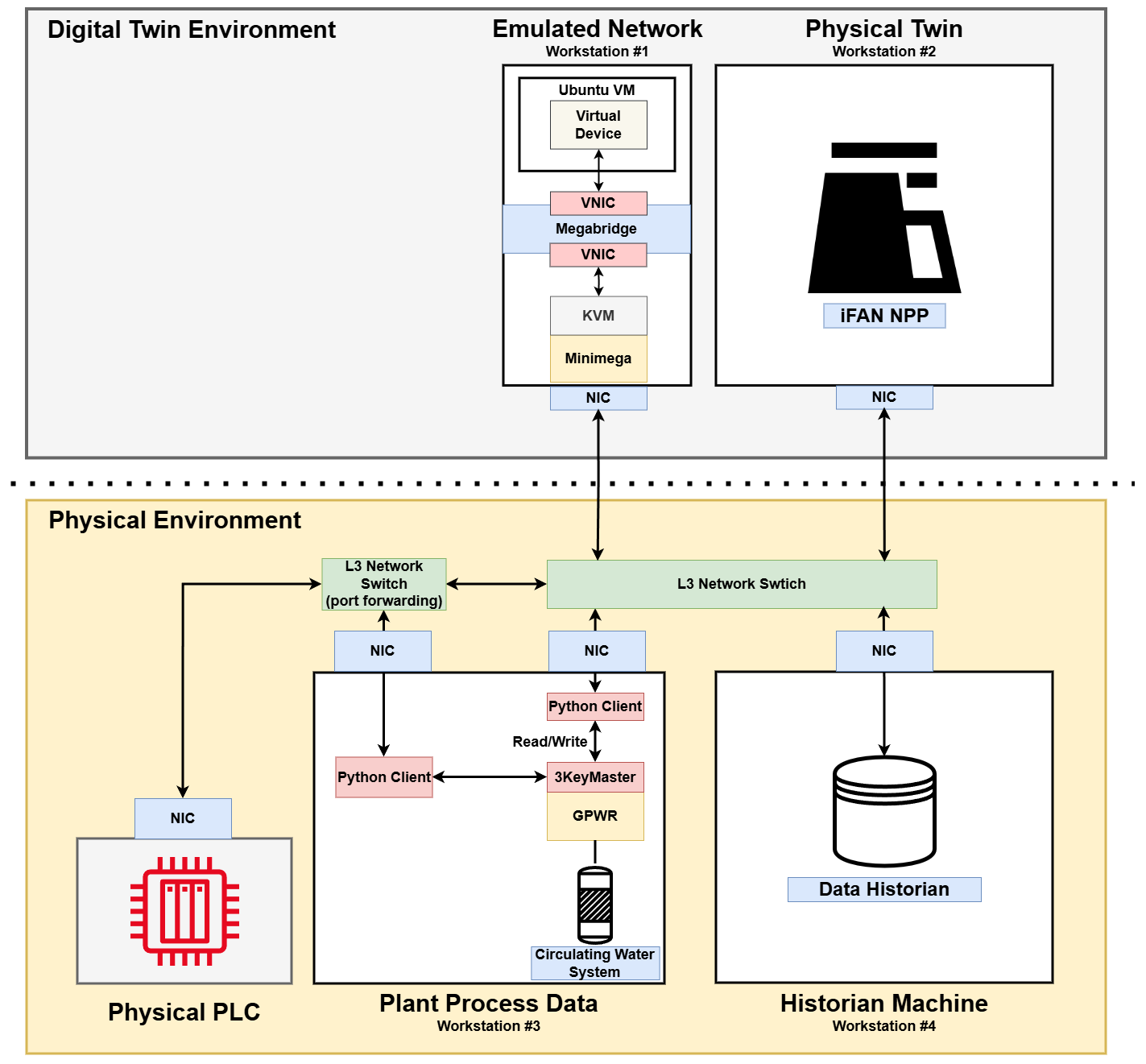

Hardware-in-the-Loop (HIL) testing establishes a connection between a simulated environment, the Digital Twin, and physical control systems. This is achieved by directly integrating actual industrial controllers, such as Rockwell Automation’s ControlLogix programmable automation controllers, into the simulation loop. Instead of solely relying on software-based simulations, HIL testing utilizes the genuine hardware that will ultimately govern the real-world process. This allows for testing and validation using the exact same logic and parameters the system will employ in operation, providing a more accurate and representative assessment of performance characteristics before physical deployment.

Real-time validation of control algorithms and system responses is achieved by subjecting the Digital Twin to a range of simulated operating conditions, including normal operation, upset conditions, and transient events. This process verifies that the control logic functions as designed within the virtual environment and, crucially, that the simulated responses accurately reflect expected behavior when implemented on the physical control system. By comparing the Digital Twin’s output to known or predicted values under varying conditions, engineers can identify discrepancies and refine the simulation model to improve its fidelity. This iterative validation process enhances confidence in the accuracy and reliability of the Digital Twin as a predictive tool and minimizes the risk of unexpected behavior during actual plant operation.

Data exchange between the physical controller and the Digital Twin environment is achieved utilizing FactoryTalk Linx as a communication gateway and the Common Industrial Protocol (CIP). This configuration enables real-time transmission of process variables and control signals, allowing the virtual environment to accurately reflect the behavior of the physical control system. Specifically, steam generator level control simulations benefit from this integration, as the physical controller’s responses to simulated plant conditions are directly translated and validated within the virtual environment, and conversely, control actions from the virtual environment are executed on the physical controller for closed-loop testing.

Expanding Operational Boundaries: Autonomous Robotics Integration

Autonomous robotic platforms represent a significant advancement in remote operations within high-risk environments, particularly when integrated with a Digital Twin. These robots aren’t simply remotely controlled; they extend the reach of human capabilities into areas inaccessible or dangerous for personnel, such as nuclear facilities or disaster zones. By operating within the virtual replica, robots can perform detailed inspections, conduct preventative maintenance, and even execute repairs without placing humans in harm’s way. This approach not only enhances worker safety but also minimizes downtime and operational costs, as tasks can be completed more efficiently and without the need for extensive protective measures or evacuation protocols. The deployment of these platforms promises a future where hazardous work is conducted with minimal risk to human life and well-being, paving the way for increased productivity and resilience in critical infrastructure sectors.

To prepare personnel for the challenges of remotely operating robots within a nuclear environment, highly realistic training simulations are now possible through the integration of Unreal Engine 5 and virtual reality technology. These immersive environments replicate the visual and operational complexities of a nuclear facility, allowing operators to practice controlling robotic platforms from a safe, virtual location. The fidelity of Unreal Engine 5 allows for accurate rendering of lighting, textures, and spatial arrangements, crucial for developing the necessary skills to perform inspections and maintenance tasks remotely. This approach not only minimizes the risks associated with direct human exposure to radiation and hazardous materials but also significantly reduces the time and cost associated with traditional, physical training exercises, creating a more efficient and effective pathway for workforce development.

Intelligent robotic control within complex environments is being advanced through the application of reinforcement learning. Utilizing simulation platforms like Airsim and Cosys Airsim, researchers are developing algorithms that allow robots to navigate and perform tasks with increasing autonomy. During training, these systems learn through trial and error, optimizing their actions to achieve defined goals. Recent results demonstrate a substantial success rate – 96% – in robot navigation during reinforcement learning training, indicating the potential for reliable performance in real-world applications and reduced reliance on direct human control within challenging or hazardous settings.

Fortifying Defenses: A Platform for Cybersecurity Resilience

A comprehensive Digital Twin Ecosystem is increasingly vital for bolstering industrial cybersecurity, functioning as a dynamic replica of the physical plant used for continuous threat assessment. This virtual environment allows security professionals to move beyond reactive measures and proactively evaluate the effectiveness of their Cybersecurity Framework against a spectrum of potential attacks. By mirroring the plant’s operations, the ecosystem enables the safe simulation of sophisticated threats – such as those targeting programmable logic controllers – without disrupting actual production. This approach facilitates the identification of vulnerabilities in system configurations, network architecture, and operational procedures, ultimately strengthening the plant’s defenses and improving its overall resilience against evolving cyber risks. The platform provides a controlled space for testing security patches, refining incident response plans, and training personnel, all contributing to a more robust and secure industrial control system.

The Digital Twin ecosystem provides a unique environment for bolstering plant cybersecurity through comprehensive simulation. Operators are no longer reliant on reactive measures; instead, they can proactively subject the system to a barrage of potential attacks, specifically including insidious Foreign Data Injection (FDI) attacks. This allows for the rigorous testing of mitigation strategies – from enhanced authentication protocols to anomaly detection algorithms – without risking actual operational disruption. By identifying vulnerabilities within the simulated environment, teams can refine security protocols, strengthen system resilience, and ultimately create a more robust defense against evolving cyber threats, ensuring continuous and reliable operation even under duress.

The Digital Twin ecosystem gains significant analytical power through the integration of Rapyuta Plugins, which function as extensions to the core simulation environment. These plugins introduce custom sensor data and unique data streams, enabling a far more granular understanding of plant behavior under both normal operating conditions and during simulated cyberattacks. By injecting these specialized data feeds, operators can move beyond generic vulnerability assessments and pinpoint subtle anomalies indicative of malicious activity. This detailed behavioral analysis is critical for developing proactive security measures, allowing for the implementation of targeted defenses and the strengthening of the plant’s overall Cybersecurity Framework before potential threats materialize. The ability to customize the Digital Twin with these plugins transforms it from a passive simulation tool into an active threat-hunting and mitigation platform.

The iFAN ecosystem, as detailed in the document, strives for a predictive consistency in its simulations-a characteristic echoed in Vinton Cerf’s assertion, “The Internet treats everyone the same.” While seemingly disparate, both concepts emphasize predictable boundaries and reliable function. The iFAN platform’s integration of digital twins, cybersecurity measures, and robotics isn’t merely about creating a functional testbed; it’s about establishing a system where interactions-whether physical robot movements or data packet transmissions-behave in a consistent, provable manner. This pursuit of predictable, reliable behavior, mirrored in Cerf’s observation about the internet’s neutrality, is foundational to ensuring the safety and efficiency of advanced nuclear operations.

Future Directions

The iFAN ecosystem, while demonstrably a step toward integrated simulation, ultimately highlights the enduring challenge of representational fidelity. The platform’s utility rests on the assumption that a sufficiently detailed digital twin can encapsulate the complexities of a nuclear facility-a proposition bordering on the philosophical. Every abstraction, every simplified model of physical processes, introduces potential divergence from reality. The question isn’t whether the simulation ‘works,’ but whether its inherent inaccuracies are systematically understood and bounded, a requirement demanding far more rigorous mathematical treatment than is currently typical.

Future efforts should prioritize formal verification techniques. Reinforcement learning algorithms, employed within iFAN, offer probabilistic solutions, not guarantees. A truly robust system necessitates provable safety constraints, not merely empirical demonstrations of resilience. Furthermore, the coupling of cyber-physical security with robotic actuation demands a deeper exploration of control theory-specifically, the development of algorithms resistant to adversarial manipulation, verified against formal models of attacker behavior.

The pursuit of comprehensive digital twins is, in essence, a quest to build a perfect mirror. Current approaches, while impressive in scope, remain reflections distorted by necessary simplification. The true advancement lies not in adding layers of complexity, but in achieving an elegant minimalism-a reduction of the system to its fundamental, mathematically verifiable components.

Original article: https://arxiv.org/pdf/2601.19234.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Lacari banned on Twitch & Kick after accidentally showing explicit files on notepad

- YouTuber streams himself 24/7 in total isolation for an entire year

- Answer to “A Swiss tradition that bubbles and melts” in Cookie Jam. Let’s solve this riddle!

- Ragnarok X Next Generation Class Tier List (January 2026)

- Gold Rate Forecast

- Best Doctor Who Comics (October 2025)

- These are the 25 best PlayStation 5 games

- 9 TV Shows You Didn’t Know Were Based on Comic Books

- 2026 Upcoming Games Release Schedule

- Best Hulk Comics

2026-01-29 05:03