Author: Denis Avetisyan

A new AI-powered platform aims to empower biomedical technicians in under-resourced regions with the tools they need to diagnose, maintain, and repair vital medical devices.

This review details INGENZI Tech, an AI-driven diagnostic and support system leveraging large language models and retrieval-augmented generation for improved medical device sustainability in low-resource settings.

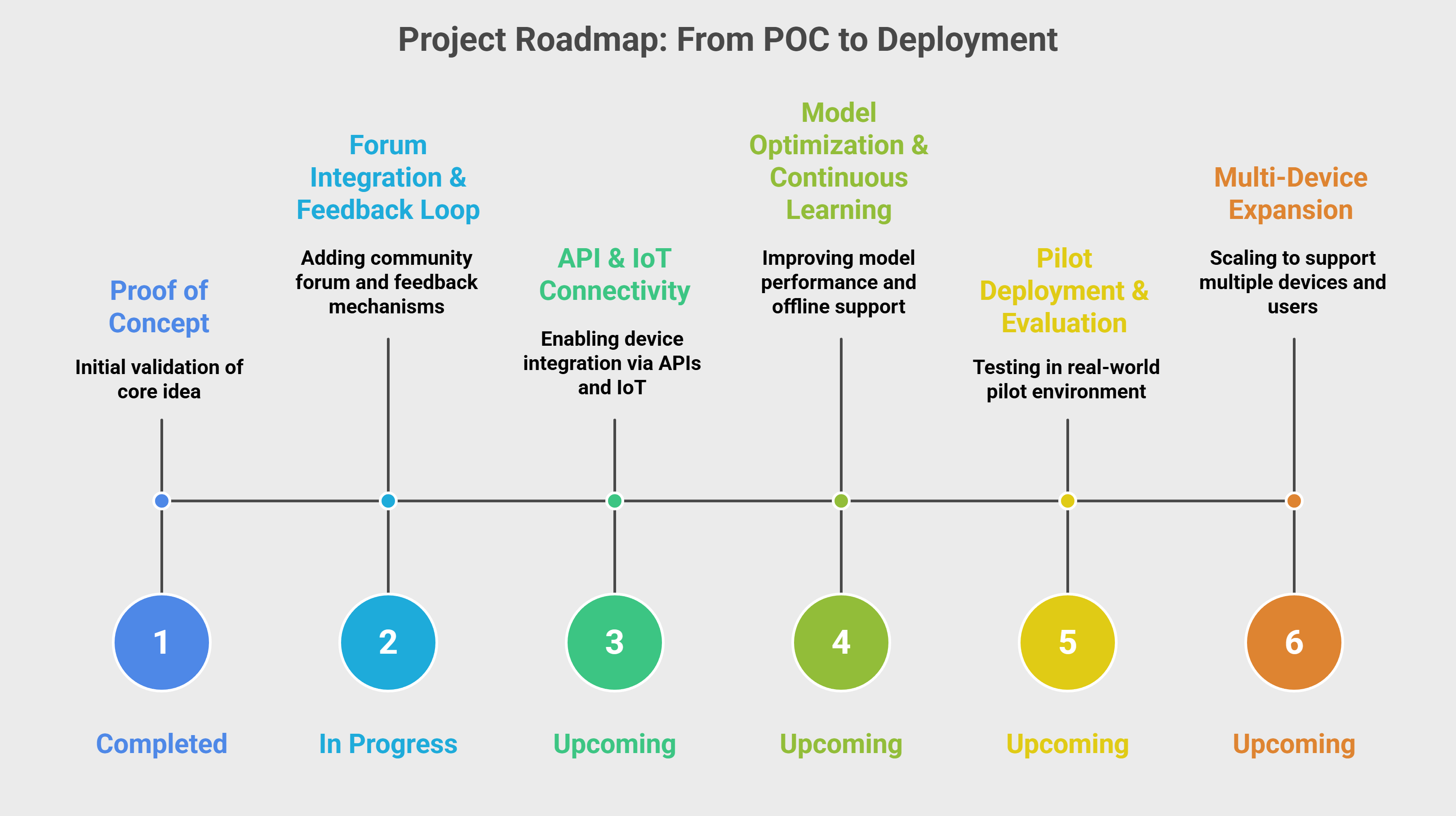

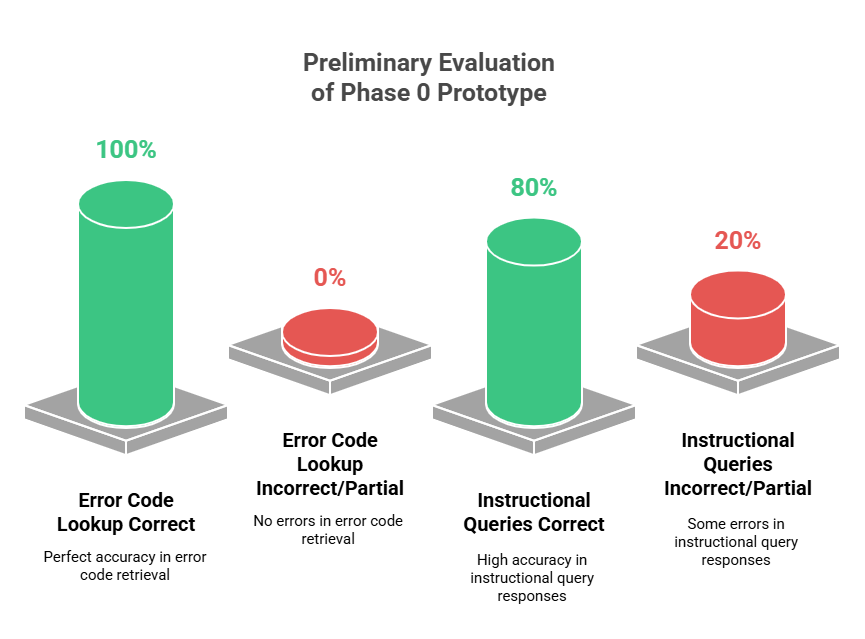

Despite advances in medical technology, a substantial portion of diagnostic equipment in low- and middle-income countries remains underutilized due to maintenance deficits and limited technical support. This research details the development and validation of an AI-powered platform-detailed in ‘Empowering Medical Equipment Sustainability in Low-Resource Settings: An AI-Powered Diagnostic and Support Platform for Biomedical Technicians’-designed to empower biomedical technicians with real-time diagnostic assistance and troubleshooting guidance. Demonstrating 100% precision in error code interpretation using a proof-of-concept with the Philips HDI 5000 ultrasound, this system integrates a large language model with a peer-to-peer knowledge forum to address critical gaps in device upkeep. Could such AI-driven solutions fundamentally reshape medical device maintenance and, ultimately, improve healthcare access in resource-constrained environments?

The Inevitable Breakdown: Why We Need Smarter Support

The scarcity of qualified biomedical technicians presents a critical challenge to healthcare delivery, especially within resource-constrained environments. This shortage directly translates to extended periods of medical device downtime, as routine maintenance and necessary repairs are delayed or simply unattainable. Consequently, essential diagnostic and therapeutic equipment falls into disuse, hindering a facility’s ability to provide adequate patient care and ultimately compromising health outcomes. The problem isn’t simply a lack of technicians overall, but a severe maldistribution; remote and underserved regions consistently experience the most acute shortages, exacerbating existing health disparities and creating a cycle of limited access to vital medical technologies. Addressing this imbalance requires innovative strategies focused on training, retention, and the development of accessible support systems tailored to the unique needs of these communities.

Current medical device maintenance often depends on voluminous, complex manuals and the sporadic availability of specialized experts, a system demonstrably ill-equipped for the demands of global healthcare. This reactive approach creates significant bottlenecks, delaying repairs and increasing the risk of equipment failure at critical moments. The logistical challenges and substantial costs associated with dispatching qualified personnel to remote or under-resourced locations further exacerbate the problem, rendering consistent, preventative maintenance impractical. Consequently, a substantial proportion of vital medical equipment in many parts of the world falls into disrepair due to a lack of accessible expertise, ultimately impacting patient care and hindering effective healthcare delivery.

The consistent functionality of medical devices hinges on a shift towards preemptive support systems, recognizing that reliance on reactive repairs and infrequent expert intervention is increasingly untenable. A truly effective solution necessitates readily available, intelligent tools that empower local biomedical technicians – those on the front lines of healthcare maintenance. This isn’t merely about providing digital manuals; it demands a system capable of guiding technicians through diagnostics, predicting potential failures, and offering tailored repair instructions, potentially leveraging augmented reality or remote expert assistance. Such a proactive approach minimizes downtime, reduces the strain on limited resources, and ultimately ensures that critical equipment remains operational, directly impacting patient care and public health, particularly in underserved regions where specialized expertise is scarce.

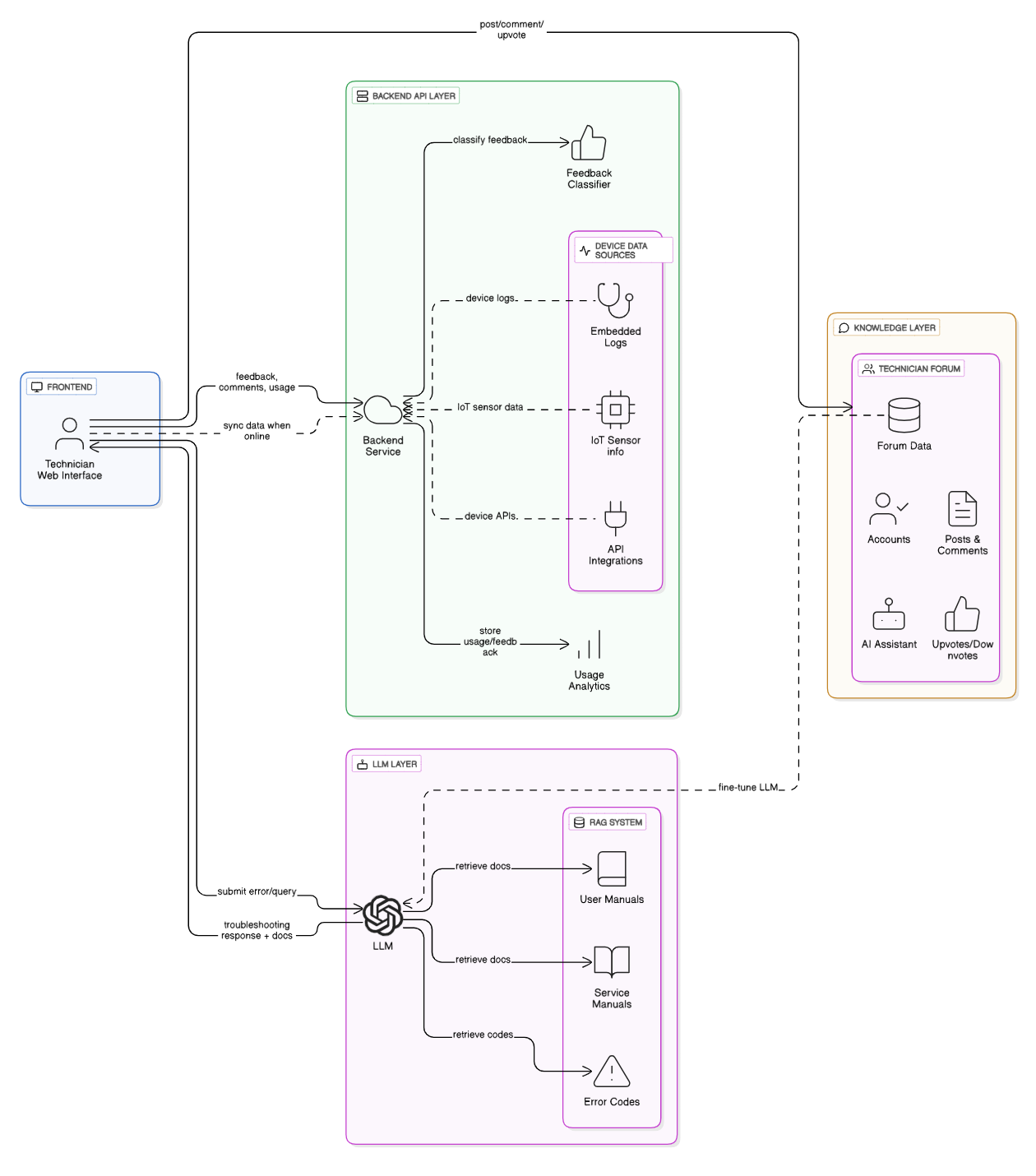

The RAG Architecture: A Necessary Compromise

The LLM-Powered Diagnostic Assistant employs a Retrieval-Augmented Generation (RAG) architecture, which integrates a large language model (LLM) with an information retrieval component. This approach overcomes limitations of standalone LLMs by grounding responses in factual, up-to-date data. Rather than relying solely on the LLM’s pre-trained knowledge, the RAG system first retrieves relevant documents from a knowledge base based on the user’s query. These retrieved documents are then provided as context to the LLM, enabling it to generate responses that are both informed by its reasoning capabilities and specifically tailored to the provided information. This combination enhances accuracy, reduces hallucinations, and allows the system to address complex diagnostic scenarios requiring precise details.

The system employs Facebook AI Similarity Search (FAISS) as its primary mechanism for information retrieval from a vector database. This database is segmented to improve search efficiency and scalability. FAISS facilitates rapid identification of documentation segments most relevant to a given query by performing similarity searches in a high-dimensional vector space. Each documentation segment is converted into a vector embedding, and FAISS indexes these vectors, allowing for approximate nearest neighbor searches to be performed with low latency. This ensures critical data is quickly accessible, supporting real-time diagnostic assistance.

GPT-3.5 Turbo serves a dual role within the diagnostic assistant: it is utilized to generate vector embeddings of the technical documentation, enabling semantic search and information retrieval, and it also powers the generation of the final, human-readable responses presented to the user. These responses are formulated based on the retrieved documentation and the user’s query. Internal testing, conducted using a standardized dataset of error codes, demonstrated 100% accuracy in the correct interpretation of these codes when utilizing this Retrieval-Augmented Generation (RAG) framework, indicating a high degree of reliability in the assistant’s diagnostic capabilities.

Collective Intelligence: Leveraging the Wisdom of the Field

A Peer-to-Peer Discussion Forum is integrated into the system to facilitate knowledge sharing among field technicians. This forum serves as a central repository for troubleshooting insights, repair procedures, and emergent issue documentation. Technicians can post questions, share solutions, and validate approaches with their peers, creating a continuously updated knowledge base. The collective intelligence generated within the forum is then leveraged to improve the overall system performance and the accuracy of its responses, ensuring that the system benefits from the practical experience of those directly involved in device maintenance.

The system leverages a semi-supervised learning process to continuously improve the Large Language Model’s (LLM) performance in device maintenance. Data generated from peer-to-peer discussions – representing technician insights and troubleshooting steps – is used to augment the initial training dataset. This allows the LLM to refine its responses without requiring fully labeled data, addressing the scalability limitations of traditional supervised learning. By incorporating this collective intelligence, the model adapts to new challenges and emerging issues in device maintenance, improving the accuracy and relevance of its instructional responses over time.

Validation of the system was performed using the Philips HDI 5000 Ultrasound as a case study, yielding 80% accuracy in responding to instructional queries based on a test set of 30 questions. Analysis of related implementations indicates a potential for 25% reduction in maintenance costs, as reported by Shamayleh et al., and a possible 20% decrease in machine downtime, according to findings by Mohamed et al. These figures suggest quantifiable benefits through the application of this technology in field service operations.

Resilience by Design: Preparing for the Inevitable Disconnect

The system addresses a critical challenge in global healthcare: the unreliability of internet access in many resource-constrained environments. Recognizing that consistent connectivity cannot be assumed, the design incorporates robust offline support capabilities. Technicians are able to download essential diagnostic guides, repair manuals, and troubleshooting workflows directly onto their devices, ensuring access to vital information even without an internet connection. This localized knowledge base empowers field service personnel to independently resolve issues, minimizing downtime and maintaining critical medical device functionality in areas where connectivity is intermittent or nonexistent. The system dynamically synchronizes data when a connection becomes available, ensuring the offline resources remain current and reflecting the latest updates and improvements.

The system is engineered for practical deployment within existing healthcare infrastructures through full compliance with established communication protocols. Specifically, integration with DICOM-the standard for medical imaging-facilitates seamless access and interpretation of visual data. Adherence to HL7 standards ensures interoperability with electronic health records, enabling efficient data sharing and reducing administrative burdens. Furthermore, the incorporation of MQTT, a lightweight messaging protocol, allows for reliable and efficient communication with a range of medical devices and sensors, even in bandwidth-constrained environments. This commitment to standardized communication minimizes integration costs and allows hospitals to leverage their current systems while benefiting from advanced diagnostic and maintenance capabilities.

The system’s core strength lies in its synergistic approach to medical device maintenance, combining intelligent assistance, continuous learning, and robust operational resilience to demonstrably improve device performance. By proactively identifying potential failures and optimizing maintenance schedules, the technology significantly minimizes device downtime and associated costs. This is supported by alignment with existing research – notably, studies achieving up to 99.4% prediction accuracy, as demonstrated by Zamzam et al., and remaining useful life estimations ranging from 92-99% utilizing CNN-LSTM hybrid models. The outcome is not merely cost savings, but a tangible enhancement to patient care through consistently reliable medical equipment and minimized disruptions to critical services.

The pursuit of elegant solutions for medical device maintenance, as detailed in this work with INGENZI Tech, feels…familiar. It’s a predictable cycle. This platform, leveraging AI for diagnostic support in low-resource settings, undoubtedly aims for robustness, yet one anticipates the inevitable edge cases production will expose. As Barbara Liskov observed, “It’s one thing to design a system, but quite another to have it actually work.” The promise of predictive maintenance and readily available troubleshooting guides is appealing, but the reality of diverse equipment, limited data, and unforeseen user interactions will test even the most carefully constructed system. Every abstraction, every LLM-powered suggestion, dies in production; at least it dies beautifully, offering data for the next iteration, and perhaps, a slightly more resilient design.

What’s Next?

The promise of AI-assisted medical device maintenance in low-resource settings is, predictably, more complex than initial enthusiasm suggests. This work, like so many before it, tackles a genuine need – keeping vital equipment operational – but introduces a new layer of dependencies. The platform, INGENZI Tech, offers a seductive vision of readily available expertise, yet hinges on the continued functionality of the AI itself, the availability of power, and, crucially, the accuracy of the data it consumes. One anticipates a swift evolution of failure modes – not just broken machines, but broken diagnoses – requiring a parallel system for validating AI outputs.

The peer-to-peer knowledge-sharing component feels particularly familiar. It echoes countless prior attempts to build ‘communities of practice’, often dissolving into echo chambers or abandoned forums. The true test won’t be the initial adoption rate, but sustained engagement and the ability to filter signal from noise. Expect a future iteration to include a ‘credibility score’ for contributors, swiftly followed by attempts to game that system.

Ultimately, this represents another iteration of a very old problem: extending the lifespan of technology in challenging environments. The underlying issues – lack of training, limited parts availability, inadequate infrastructure – remain. This platform addresses symptoms, not causes. And, as always, the next ‘revolutionary’ framework will likely be the old thing, repackaged with a slightly shinier interface and significantly worse documentation.

Original article: https://arxiv.org/pdf/2601.16967.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Lacari banned on Twitch & Kick after accidentally showing explicit files on notepad

- YouTuber streams himself 24/7 in total isolation for an entire year

- Ragnarok X Next Generation Class Tier List (January 2026)

- Answer to “A Swiss tradition that bubbles and melts” in Cookie Jam. Let’s solve this riddle!

- Gold Rate Forecast

- ‘That’s A Very Bad Idea.’ One Way Chris Rock Helped SNL’s Marcello Hernández Before He Filmed His Netflix Special

- Every Major Assassin’s Creed DLC, Ranked

- Shameless is a Massive Streaming Hit 15 Years Later

- 9 TV Shows You Didn’t Know Were Based on Comic Books

- These are the 25 best PlayStation 5 games

2026-01-27 07:39